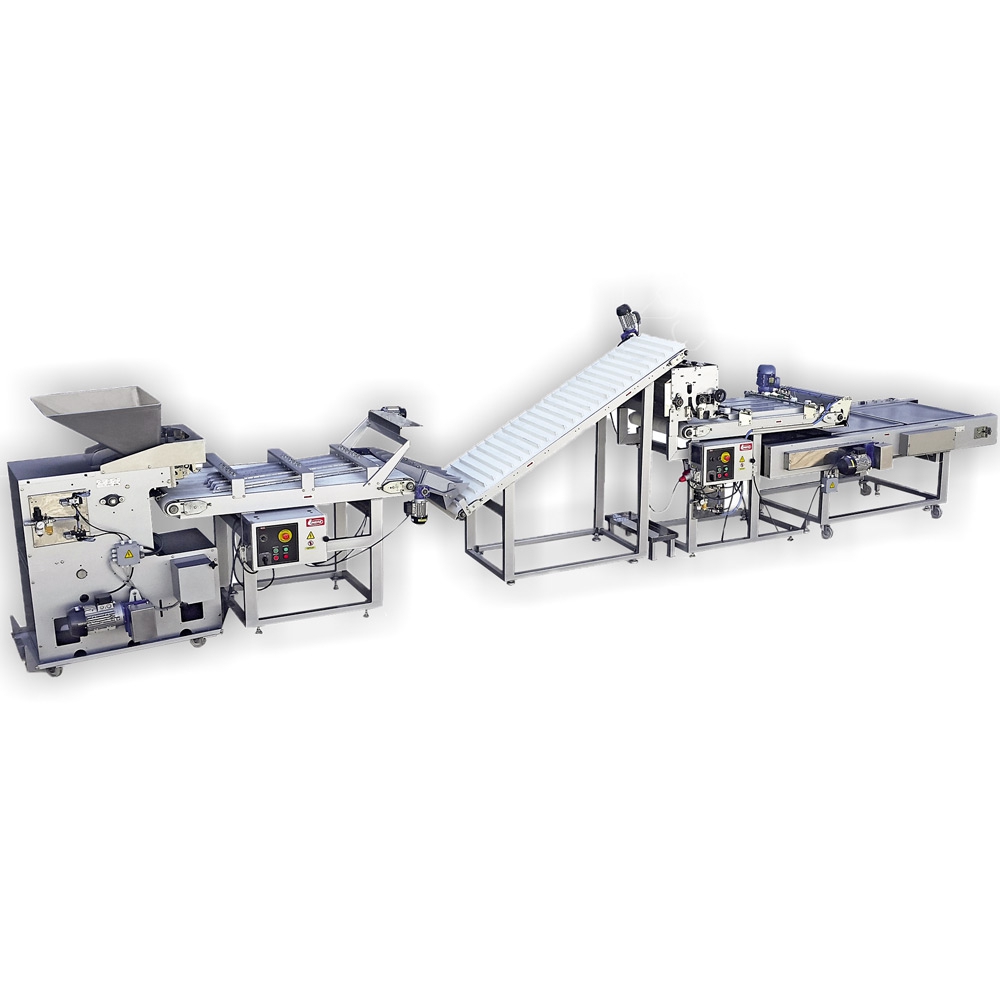

Hamburger. Hot Dog and Pastry Line Model LH-5000

The LH-5000 line is designed for the production of various Vienna bread, pastries, hot dog buns, hamburgers, Pebete, etc., intended for fermentation, baking, and subsequent demolding. The operation of the line begins with the Divider, which is manually fed through a bowl elevator or a transfer belt. With a dough division range from 20 to 100 grams, a cutting precision of +/- 2%, and a production range of 6,000 to 7,200 rolls per hour.

The volumetric divider delivers 4 rolls simultaneously, depositing them on the molding belt through a pneumatic scraper. The rounder gives the 4 rolls a rounded shape, and after dusting, deposits them on the elevating belt through channels. The lifting belt transports the roll, with a resting period, to the laminating head. This head is composed of 2 large-diameter rollers, each with its adjustable scraper that conditions the dough to the speed of the assembly belt.

This assembly does not have chains or belts, is easy to maintain, and plays a crucial role in the quality of the bread. It is constructed with rollers coated with non-stick material, allowing it to work with high-moisture dough. The 4 rolls are simultaneously guided to each assembly drawer through adjustable guides.

The assembly system is reliable and secure for this type of roll, suitable for hot dogs, sausages, small bread, Vienna bread, Pebete, etc.

The laminated roll enters the assembly channel with adjustable lateral containment, generating individual assembly for each of the 4 rolls simultaneously. For hamburger buns, figaza, flatbreads, or similar, simply crushing the rollers completes the product. The reliability of the IMEPA working system is suitable for the high level of production that a system of these characteristics requires.

At the end of the assembly line is the automatic tray depositing unit activated by gates to align the rolls after rolling and/or assembly, placing them on the tray automatically without leaving empty channels or generating double rolls. This simplifies the operators task, who only needs to place empty trays and remove the filled ones. The trays or molds to be used are defined by the customer and do not need a specific shape or care about their condition regarding parallelism, deformations, false squareness, breakage, etc.

Since the feeder contains them and operates independently. All operations from the beginning (divided dough piece) to the final assembly and tray deposition are completed within 1 minute of real-time. This gives the equipment a significant advantage in the production of products with a high yeast content, preventing the dough from fermenting during the bread shaping process.